Novel power electronics for OnBoard Chargers, DC-DC Converters and Solar Inverters

Technology with a particularly high power density of more than 3kW/litre, enables among other things, a significant reduction in charging times for electric vehicles.

KYOCERA AVX Components (Salzburg) has been a global player in the power electronics market for many years, and is known for innovative technologies that can be installed in very confined spaces. The latest development, which won third place in the WIKARUS innovation competition held by the state of Salzburg, is the first to use a completely new semiconductor technology that uses gallium nitride instead of silicon.

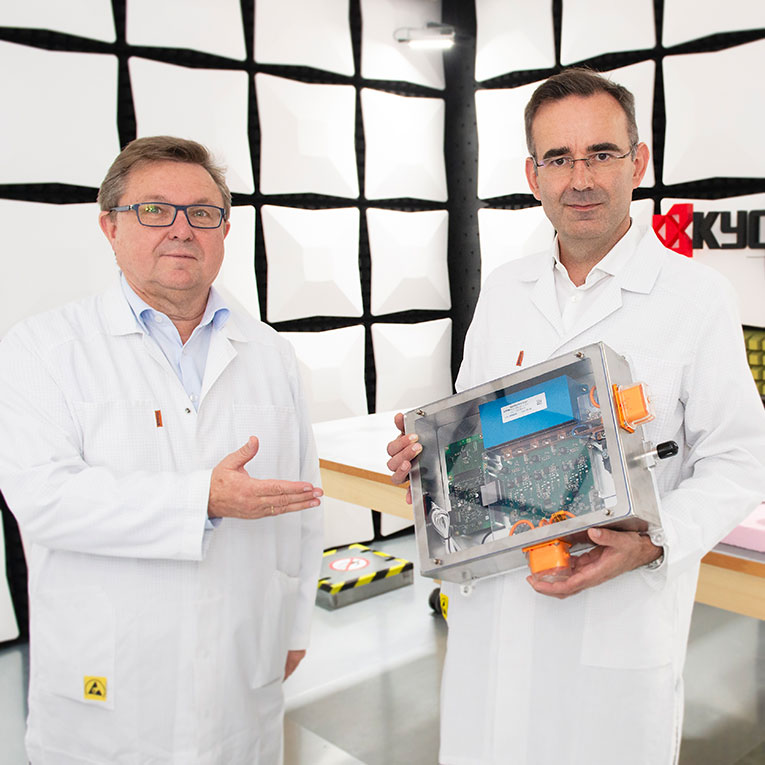

From left to right: Georg Schafrath (Managing Director) and Gerhard Köck (R&D Manager); both KYOCERA AVX Components (Salzburg) GmbH; © KS/Hauch

DC voltage is converted into pulses with low loss

In all DC-DC applications it is necessary to split the DC voltage into pulses. This high-frequency on and off switching results in high power losses. Using new semiconductor technology and optimized current management, a significant increase in switching frequencies can be achieved, while simultaneously reducing losses.

Novel technology enables power density of more than 3kW/litre

This technology was developed with a focus on on-board chargers (chargers installed in the vehicle). The core element is a very low inductance design that makes it possible to greatly increase the switching frequencies. By using a new semiconductor technology (gallium nitride), this high switching frequency can be implemented with very low power losses.

Small footprint means higher performance and shorter charging times

The consistent approach to reducing power losses leads to a very compact design, high efficiency and, most importantly, leads to economic advantages. In addition, the higher power density makes it possible to markedly increase, and in some cases even double, the power output for a given installation space. This becomes tangible when, for example, considering halving the charging time for a passenger car.

Georg Schafrath (Managing Director) and Gerd Köck (R&D Manager) at KYOCERA AVX Components (Salzburg) are delighted with their recognition in the WIKARUS Innovation Competition, and are confident in their highly effective invention. Faster charging times are a particularly important focus for the Salzburg experts, as their innovative solutions make an important contribution to the future adoption of electric drives.

The overall strong economic case makes the innovation attractive for versatile application in the automotive industry, but it is also suited for use in solar inverters. For a technical discussion, please contact us here.