Electronics for the Exhaust System

Trust In Competence –

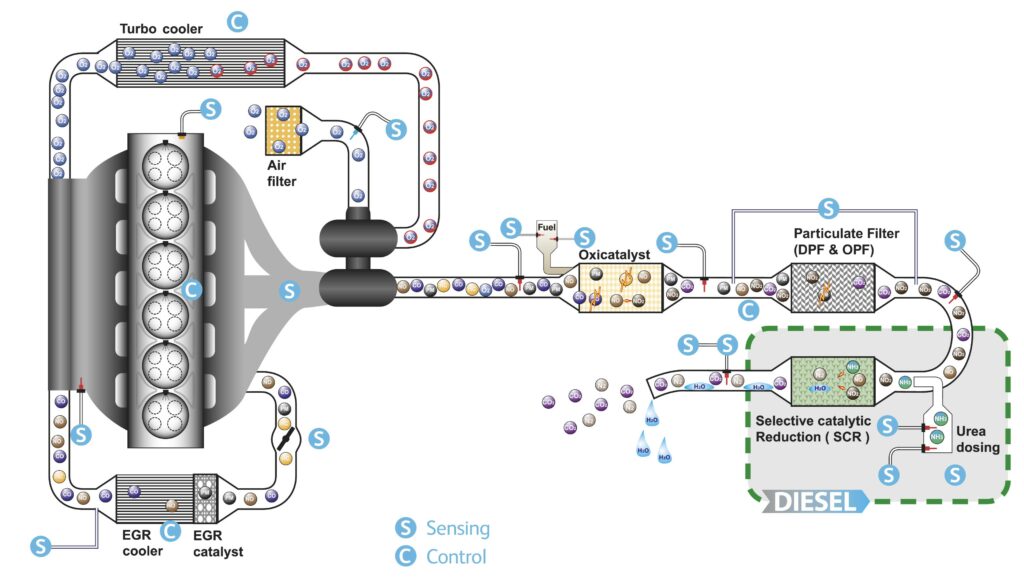

Sensors and Power Electronics for the Exhaust System

We have been partners of European premium manufacturers for many years. Our experts have been involved in the development process and exchange of experience on the subject of emissions after-treatment since discussions began on fuel consumption and cutting emissions.

Being involved from the start means knowing the stages of Euro 4 and Euro 5 as well as Tier4i and f and the associated enhanced requirements, optimisation potential and finally also the solutions in detail. Today we are contributing this experience to the Euro 6 projects and together with our customers, designing reliable, sturdy solutions for the next generation of environmentally friendly exhaust systems.

Conditions in the exhaust system and up- and downstream systems are demanding, since many sensors have to function directly in the exhaust gas flow. High temperatures and aggressive air particles cannot be allowed to influence either reliability or service life, nor may the screening required restrict the reaction times. The better known these requirements and their integration in the product development process, the better customised development can be realised.

The field of exhaust after-treatment is one of our core competences. Apart from the product information on our homepage, we provide information in the context of presentations, specialist conferences and as part of our press work. We have put together a range of useful information and links for you on these pages. Feel free to find out all you need here. We would be pleased to receive your questions and suggestions.

Find out more about Pressure and Temperature recording in the Exhaust System

A multitude of processes is based on the recording of pressure and temperature values in the exhaust system. The solutions from KYOCERA AVX were especially developed for this use and are capable supplying the control unit with the signals needed quickly and precisely even under very aggressive ambient conditions.

Many years of experience and continuous optimisation of our portfolio have created significant advantages for each customer application. Here some examples:

Once the maximum soot particle loading has been reached, a controlled combustion process occurs to regenerate the diesel particle filter. KYOCERA AVX provides sophisticated sensor concepts both for the initiation as well as the monitoring of this process. Apart from securing the pure functionality in these demanding ambient conditions, we have succeeded in generating comprehensive optimisations, which offer decisive advantages vis-a-vis conventional systems:

Differential pressure sensor records the loading condition of the particle filter and initiates the regeneration process.

Unlike conventional designs in which the exhaust gas is also conducted on the passive side of the differential pressure measuring cell, i.e. on the electronic side of the measuring cell, we work with a two-cell system, in which only the passive side of the cells comes into contact with exhaust gas. Apart from long term stability, this principle in addition makes it possible to output the exhaust back pressure as well as the differential pressure.

High temperature sensor monitors the combustion process

High temperature sensors from KYOCERA AVX monitor this critical process and meet the highest demands regarding material selection and tightness. By using a deep-drawn housing tube, a welding point, and as a result a potential risk, is avoided in the exhaust flow. The great sturdiness of the sensor has undergone constant improvements during the course of many years of field trials.

Sensors from KYOCERA AVX protect systems against overheating

Sensors from KYOCERA AVX protect systems against overheating

The emission reduction in the case of particularly high performance engines is a challenge, since performance losses are not tolerated and the performance of the premium vehicles may not suffer in any respect.

Consumption has been further cut by novel, electronically managed combustion processes in the latest premium engine generation. For this purpose the combustion process is managed to ensure that very high exhaust gas temperatures occur. To achieve maximum exploitation of the system's potential, exhaust gas temperatures of almost 1000 °C are permitted. The materials used in the exhaust gas system and turbocharger set technical limits to any further increase.

Real-time temperature monitoring required

As a result, the exhaust gas temperature is monitored in real time using a fast high temperature sensor. In the event of an imminent temperature overrun, the engine management can initiate targeted restriction or lowering of the exhaust gas temperature without this incurring an unwanted restriction in performance.

High temperature sensor with PWM, SENT or CAN signal output

KYOCERA AVX has developed a new sensor concept with integrated electronic analysis for this application. A sophisticated high temperature sensor, endowed with sturdy, long-term resistance to the tough ambient conditions, which simultaneously provides fast, high precision signals.

The special benefit of this product development is its integrated sensor electronics, which are capable of outputting the signals in digital format with PWM or SENT protocol, depending on customer requirements.

Manufacturers of turbocharged vehicle engines can deploy pressure and temperature sensors in the exhaust manifold (before the turbocharger) to warn of excessive temperature and pressure that can damage the turbocharger.

Manufacturers of turbocharged vehicle engines can deploy pressure and temperature sensors in the exhaust manifold (before the turbocharger) to warn of excessive temperature and pressure that can damage the turbocharger.

Temperature and pressure sensors in this area are suitable for up to 1,200°C or 6 bar. With these characteristics, the sensors can be used at any point in the exhaust pipe of petrol engines as well.

Pressure and Quality Monitoring of AdBlue® in the SCR System

Since the introduction of the Euro 5 standard, the NOx content of exhaust gases in powerful diesel engines has been reduced. This is achieved by the metered supply of urea, the so called AdBlue®, into the exhaust gas stream.

AdBlue® is kept available as medium in a separate container and added to the SCR system. Compliance with the statutory regulations in force is decisive for the flawless quality of this substance, which by law requires permanent electronic monitoring. In addition, improper filling or dilution of the liquid can damage the downstream systems. The freezing point of AdBlue® presents another challenge, since from -11 °C it becomes solid. Depending on the design of the SCR system, correspondingly sturdy pressure sensors are used.

KYOCERA AVX´ solutions have been developed especially for this use. Many years of experience and continuous optimisation of our portfolio have created significant advantages for each customer application. Here some examples:

Frost from -11 °C leads AdBlue® to freeze and the associated volume expansion poses challenges for the design of SCR dosing systems and the integrated pressure sensors.

The great sturdiness of the sensor has undergone constant improvements during the course of many years of field trials. In SCR dosing systems with compressed air support, KYOCERA AVX employs inline pressure sensors with a special internal structure to facilitate effective purging of the AdBlue® before the vehicle comes to a standstill. Temperature measurement can be optionally integrated in the sensor.

KYOCERA AVX has developed a special pressure sensor for unpurged systems, which given suitable adjustment to the overall system, permits unproblematic freezing here too.

The AdBlue® quality sensor from KYOCERA AVX meets the requirements for systems in cars, trucks and off-road applications.

The AdBlue® quality sensor from KYOCERA AVX meets the requirements for systems in cars, trucks and off-road applications.

The compact, cost-optimised design is resistant to environmental influences like dirt and temperature fluctuations and aging processes.

Designed as a refractometer, the sensor measures the refractive index of AdBlue® and provides temperature-compensated information according to the effective medium concentration. Incorrect fillings or inadmissible admixtures are detected immediately and as a result consistent AdBlue® quality guaranteed in the SCR system and AdBlue® tank.

Flexible installation solution for new applications and retrofitting

The technical solution chosen permits KYOCERA AVX to implement a very sturdy sensor combined with maximum cost efficiency. The sensor can be mounted on the bottom of the AdBlue® tank or as in-line solution between the tank and dosing system. Apart from implementation in new applications, this solution is also recommended for retrofitting in existing systems.

Individual solutions are our strength.

Together we will find the best option for your project.

An extraction of our customized portfolio is available in standard designs.

Temperature. Pressure. Level. Quality. Speed. Position. Sensors, Pedals and Control Units from KYOCERA AVX reliably determine and control customer-specific applications with high accuracy.