Position Sensors

from KYOCERA AVX Components (Werne)

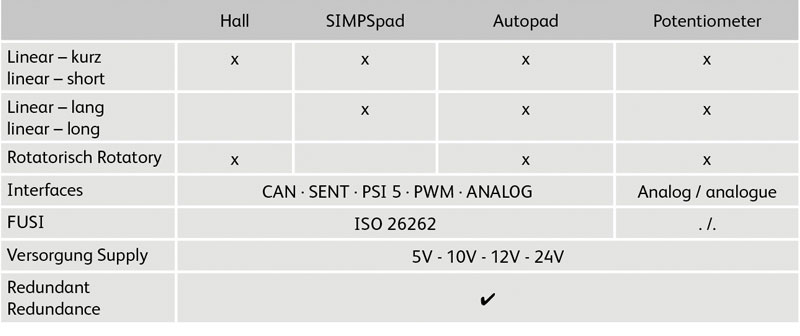

KYOCERA AVX (Werne) has been developing and producing position sensors since 1990. Our company holds a large number of patents as well as many years’ experience in the field of non-contact technologies. This enables us to tailor the product properties to the respective application. Interfaces to analog, PWM, PSI5, SENT, CAN, LIN and other protocols are possible.

Special features:

- Proprietary technologies

- Volume application in passenger cars and commercial vehicles

- Shorter runs for special vehicles and agricultural applications

The individual design of position sensors is based on selection of the optimum technology for the application, in combination with a suitable mechanical interface. Based on our specially developed advanced overmoulding techniques, we use the outstanding properties of thermoplastics and thermosets to offer our customers sophisticated enclosure solutions for assemblies with integrated sensors.

Position sensors differ fundamentally between rotary and linear sensors, and within these classes in terms of the mechanical interface required and the packaging.

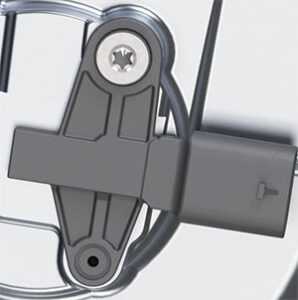

Lever-mounted angle sensors are either inductive - using a PCB-based design that provides extensive flexibility - or directly encapsulated with Hall-based technology for a particularly slim design. Angle sensors with levers are often used in the application together with rods, which have also been part of our design and scope of delivery for decades.

Application example

As a height sensor (HSS) combined with a linkage, the angle sensor with the acquisition of the chassis level of the vehicle serves to regulate the headlamp range or active chassis. Other applications that are connected with a linkage (e.g. clutch and brake pedals) can also use the HSS.

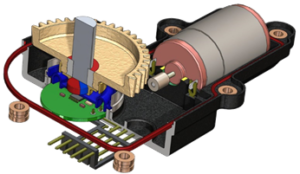

Sensor covers are used wherever rotary actuators adjust flaps and valves, and where precise information on the adjusted position is required over the entire temperature range. With advanced overmoulding technology, robust covers can be created that have the appropriate measurement technology built in, and in addition to the sensor electronics, also contact other components via the integrated connector and seal the application.

Application examples

- Exhaust gas recirculation (EGR)

- Thermal management

Sensor technology with shaft stub mounting allows for direct acquisition of shaft rotation from a position at the end of the shaft. Using temperature resistant technology, these sensors provide accurate position signals even in demanding applications. With a Hall-based design, a completely non-contact version without mechanicals is also possible by installing the magnet on the application side.

Application examples

- Throttle valve sensor

- Swirl damper sensor

Equipped with a robust design, this all-rounder among the Hall sensors is suitable for a wide variety of applications. With the existing shaft stub, it can be supplied with a linkage on the application side, or directly pick up the rotation information at the end of shaft position of the rotation axis.

Application examples

- Lever position

- Pedal

Contactless linear displacement sensor

Parking lock sensor

In automatic transmissions with electric actuators, the parking lock sensor identifies the position of the parking lock cylinder in the end positions as well as in the intermediate areas and transmits the information to the control unit.

Neutral gear detection sensor

Gearboxes with a start / stop function can activate this function only when the shift fork is in the neutral position. The neutral gear detection sensor is installed on the gearbox and ensures reliable identification of the position from the Hall sensor, based on a magnet installed in the application.

Switch fork position sensor

The shift fork position sensor detects the linear position of a permanent magnet on the shift fork in double-clutch gearboxes.

More Information about our Position Sensors:

» Locate KYOCERA AVX´s position sensors in applications such as chassis, transmission and powertrain applications

» You can find an overview of off-the-shelf sensors here

» Find technical details about our sensors in our data sheets and fast fact sheets

» Find more information about our Autopad® technology

Typical applications for our products:

Clutch detection, damper position, cylinder position, height sensor. Combined with a linkage, the angle sensor with the detection of the chassis level on the vehicle serves for headlamp levelling or control of the active chassis. Other applications connected to a linkage (e.g. clutch and brake pedals) can also use the HSS. EGR, thermal management, throttle valve sensor, swirl valve sensor, lever position, pedal, parking lock sensor, neutral gear detection sensor, transmission with start / stop function, shift fork position sensor detects the linear position of a permanent magnet on the shift fork in dual clutch transmissions, clutch position, brake cylinder position, steering actuator (front + rear), lift: pneumatic cylinder in height-adjustable chassis, dampers

Our sensors support the focal points of future mobility:

Emission reduction, E-mobility, Energy efficiency