Motor Control Units

Motor Control Unit (MCU) for Brushless DC Motor (BLDC Motors)

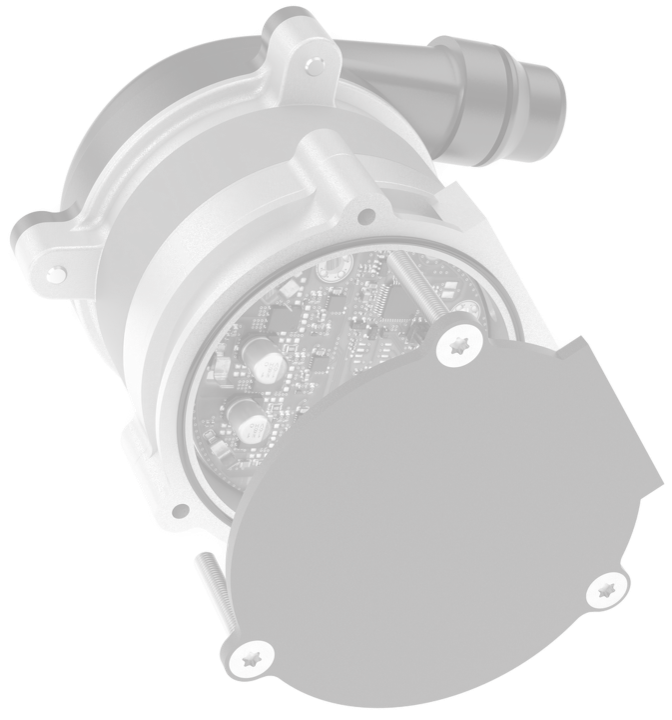

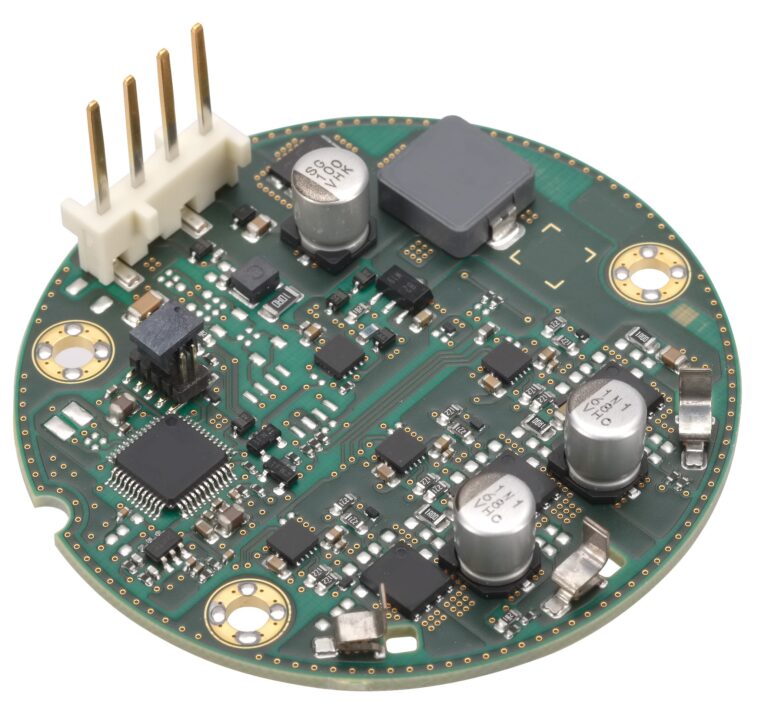

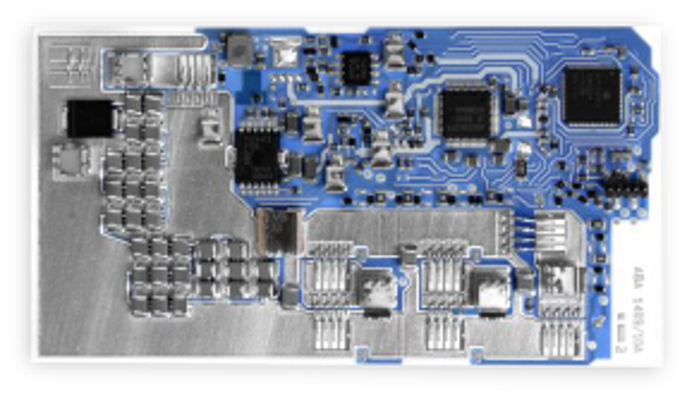

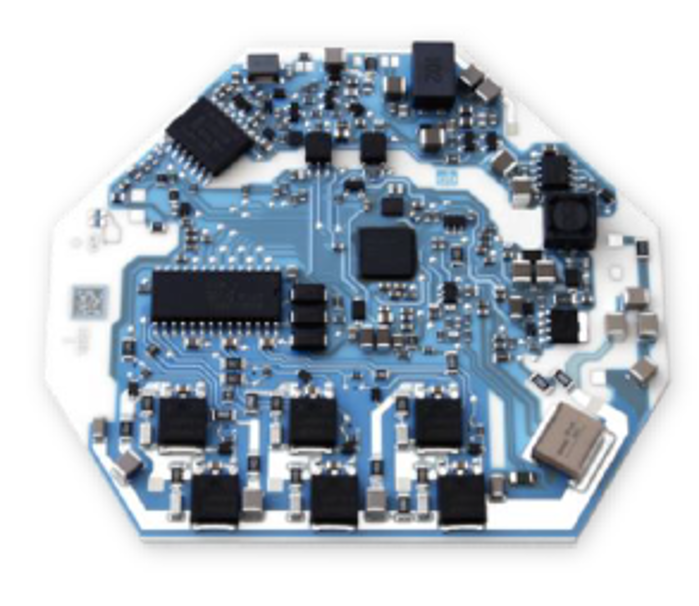

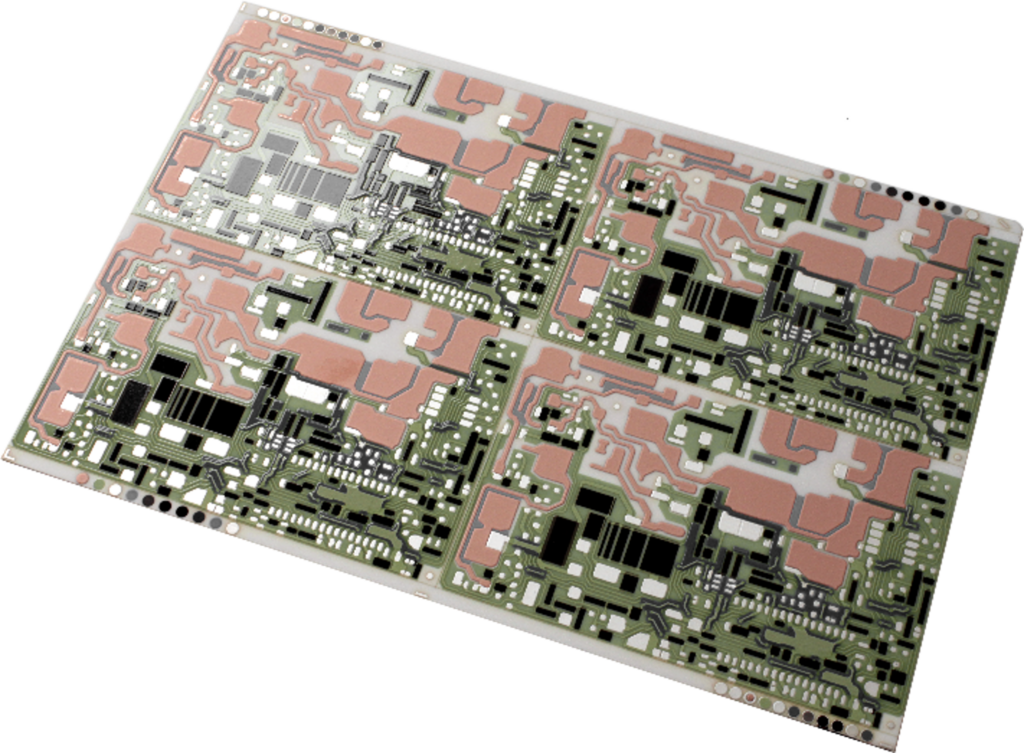

A customer-specific control unit from KYOCERA AVX (Salzburg) provides significant advantages for integration into the electric motor and into the existing installation space. The modules contain all the necessary components for the control of a brushless DC motor (BLDC motor). Their design is adapted, via the selection of the electrical components and the mechanical fasteners, also to the smallest installation space requirements and coordinated perfectly with the respective application. The comprehensive know-how of several product generations is used via sophisticated thermal and mechanical simulation. Each control unit meets the requirement of a perfectly coordinated solution with regard to space, reliability, manufacturability and cost efficiency. The specially developed contact and connecting elements also contribute to this and permit optimal connection to the external connector and, besides the mechanical reliability, provide an important cost advantage. Increasingly shorter development times in the automotive industry are achieved via specially developed platforms for hardware and software solutions. In that way it is possible to make the first prototype available within a few weeks and to successfully implement a closely coordinated project schedule as far as series production. All the platforms can be adapted at any time to the needs of other applications and automobile manufacturers. This applies to the power (30 W – 10 kW), to the on-board voltage (12 V – 810 V), and to the required communication (PWM, LIN, CAN) with the control unit.

Special characteristics

- High temperature range (-40 to + 150 °C)

- High performance in a small installation space

- High vibrations permissible, attachment to combustion engine and transmission possible

- Complete integration into the electric motor due to high integration density

- Customized design

Typical applications

- Water pumps

- Oil pumps

- Air pumps

- Electric refrigerant compressor

- Electronic crankcase ventilation

- Heat pumps

- Vacuum pumps

- Intercooling

- Filter drive

- Blower

- E-turbocharger

More information about

Motor Control Units

Products from this area are also known under the following keywords:

Inverters, motor control unit, electric drive, electrification

» On a nutshell – Download Fast Facts

Platform

| Voltage | 12 V | 24 V | 48 V | 470 V | 810 V |

| Power | 20 W – 600 W | 100 W – 1.2 kW | 200 W – 7 kW | 700 W – 7 kW | 700 W – 10 kW |

| Temperature | -40 – +150 °C |

||||

| Substrate | FR4-PCB or thick film ceramics (DPC, DBC, AMB) |

||||

| Service life | 8,000 h – 30,000 h |

||||

| Communication | PWM, LIN, CAN |

||||

Ceramic solutions

For more than 40 years, KYOCERA AVX (Salzburg) has been developing and producing customer specific ceramic circuit boards with our in-house screen-printing department.

Our experienced employees can design and produce custom ceramic solutions flexibly, efficiently, and simultaneously in an optimised manner.

Special characteristics

Ceramic substrates maximize performance in minimal space, have high integration density (intelligent logic components), are resistant to high temperatures, improve thermal dissipation and maintain great insulation properties and reliability.

- Various connecting possibilities

- Multi-layer structure

- Different metallisation options

- Printed precision resistors

Typical applications

Customer-specific modules for applications in the

- Automotive sector

- Industrial area

- Aerospace and medicine for long service life requirements

More information

about Ceramic

solutions

Products from this area are also known under the following keywords:

Power electronics, e-mobility, high voltage application, thermal conductivity, ceramic modules, ceramic heating elements

Our controls support the focal points of future mobility:

Thermal conductivity, insulation capacity, high power density, safety, and durability

Application-specific data

Screen printing technology |

|||||||

| Aluminium-oxide Al2O3 | 93 – 99 % Al2O3 | 22 – 28 W / mK | CTE ≈ 7 ppm / K | Substrate thickness: 0.2 – 1.2 mm |

|||

| Aluminium nitride AIN | 98 – 99% AlN | 180 – 230 W / mK | CTE ≈ 5 ppm / K | Substrate thickness: 0.25 – 1.6 mm |

|||

| Silicon nitride Si3N4 | ≈ 100% Si3N4 | 50 – 60 W / mK | CTE ≈ 3 ppm / K | Substrate thickness: 0.2 – 0.4 mm |

|||

| Paste technology | Silver | Silver-palladium | Silver-platinum | Silver-platinum-palladium | Platinum | Gold | Copper |

| Dielectric | Glass with ceramics filler |

||||||

| Thick film | 5 µm – 500 µm |

||||||

| Thin film | 0.01 µm – 1 µm |

||||||

Electromobility - Sensors and Controls

As electromobility gains more and more importance, we too want to be actively involved and support our customers at this environmentally friendly alternative to conventional vehicles. We offer solutions for electro and hybrid vehicles according to customer specific application.