Category: Show Picture

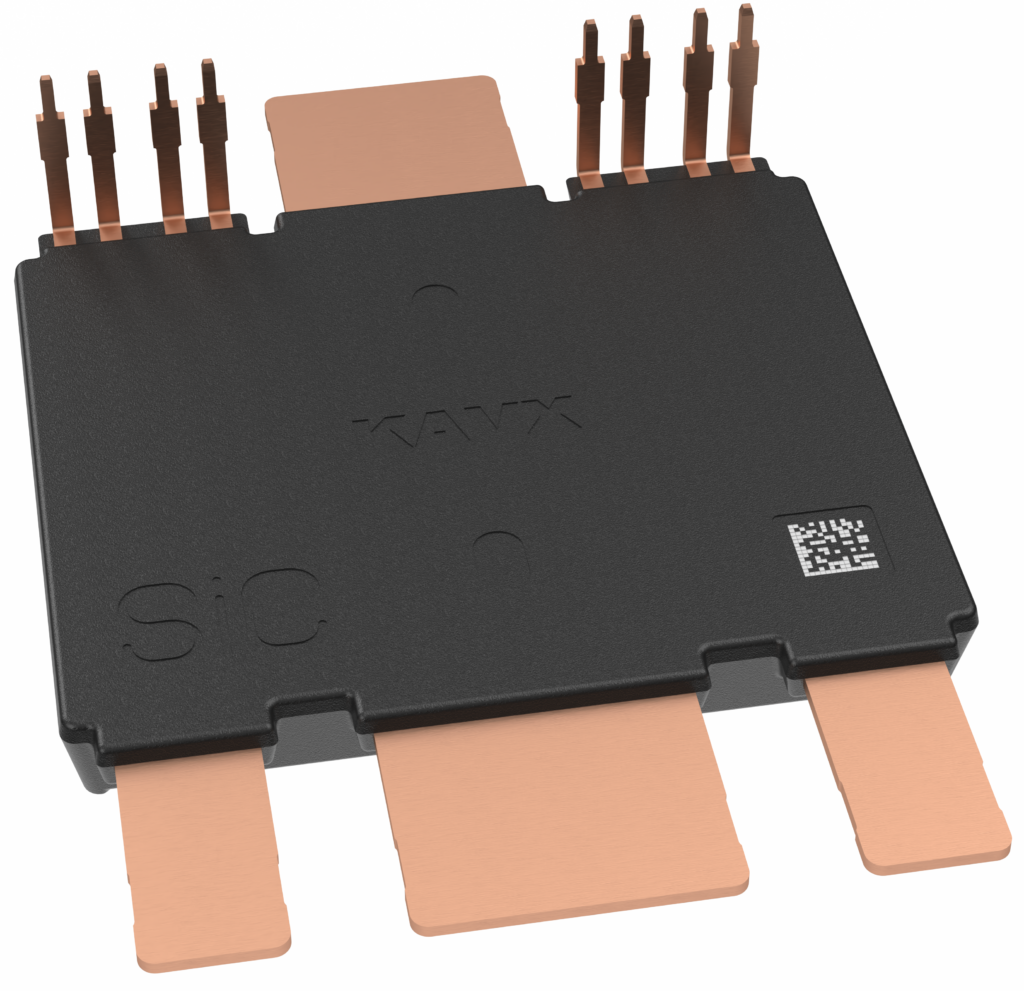

KYOCERA AVX Salzburg partners with Nexperia to produce a 650 V silicon carbide rectifier module for power applications

Joint collaboration on SiC modules brings the next step in module compactness and maximum power density

KYOCERA AVX Components (Salzburg) GmbH, a leading international supplier of advanced electronic components, today announced it has entered into partnership with Nexperia, the essential semiconductor expert, to jointly produce a new 650 V, 20 A silicon carbide (SiC) rectifier module for high frequency power applications ranging from 3 kW to 11 kW power stack designs, aimed at application like industrial power supplies, EV charging stations, and on-board chargers. This release will represent a further deepening of the existing, long-lasting partnership between the two companies.

Space-saving and weight reduction are the key requirements for manufacturers of the next generation power applications. The compact footprint of this new SiC rectifier module will help to maximize power density, thereby reducing the amount of required board space and lowering the overall system cost. Thermal performance is optimized using a combination of top-side cooling (TSC) and an integrated negative temperature coefficient (NTC) sensor which monitors the device temperature and provides real time feedback for device or system level prognosis and diagnosis. This rectifier module has a low inductance package to enable high frequency operation and it has been qualified to operate with a junction temperature of up to 175 °C.

“This collaboration between Nexperia and KYOCERA AVX combines cutting edge silicon carbide semiconductors with state-of-the-art module and will allow Nexperia to better serve the market demand for power electronic products which offer exceptionally high levels of power density,” according to Katrin Feurle, Senior Director of the Product Group SiC at Nexperia. “The release of this rectifier module will represent the first step in what is envisaged as a long-term SiC partnership between Nexperia and KYOCERA AVX”.

Thomas Rinschede, Deputy Vice President Sensing and Control Division at KYOCERA AVX Components Sensing and Control Division, comments: “We are delighted to further extend our successful partnership with Nexperia into the production of silicon carbide modules for power electronics applications. Nexperia’s manufacturing expertise combined with KYOCERA module know-how make a compelling offering for customers looking to achieve higher power densities using wide bandgap semiconductor technology.”

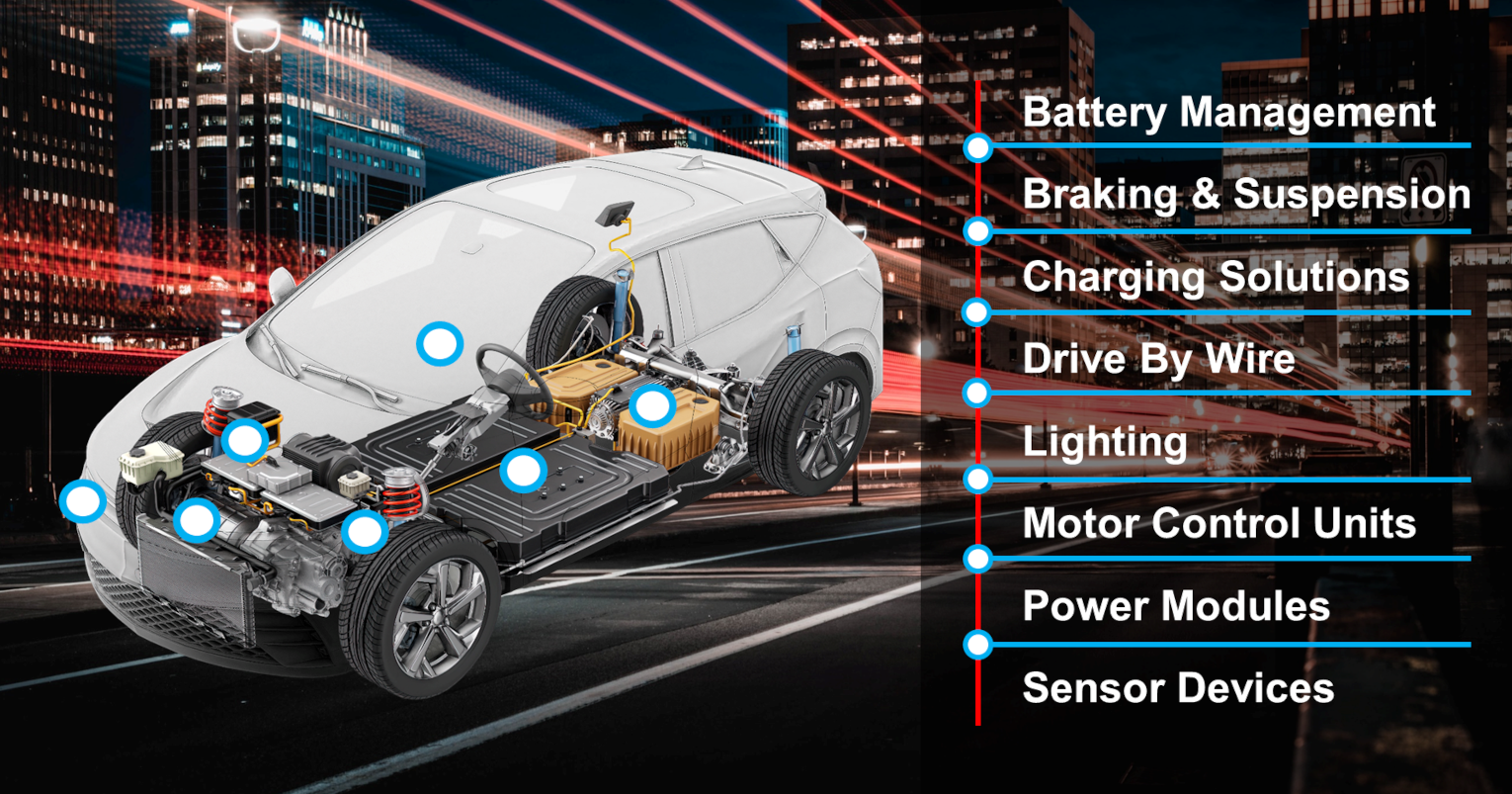

Electromobility – Sensors and Controls

As Electromobility gains more importance, KYOCERA AVX Components is actively involved and support our customers with the environmentally friendly alternative to conventional vehicles offering solutions for E- and hybrid vehicles to protect our environment and impact our future mobility. We design, develop and produce intelligent sensor systems and control units for the global automotive industry. Making engines more efficient, emissions cleaner, cars safer our products support the transition to electromobility. Discover our sensor, switches and controls, designed to meet the challenges of the demanding areas of electromobility to move your business further.

Our wide product portfolio comprises innovative solutions in the areas of

- Battery Management

- Braking & Suspension

- Charging Solutions

- Drive By Wire

- Lighting

- Motor Control Units

- Power Modules

- Sensor Devices

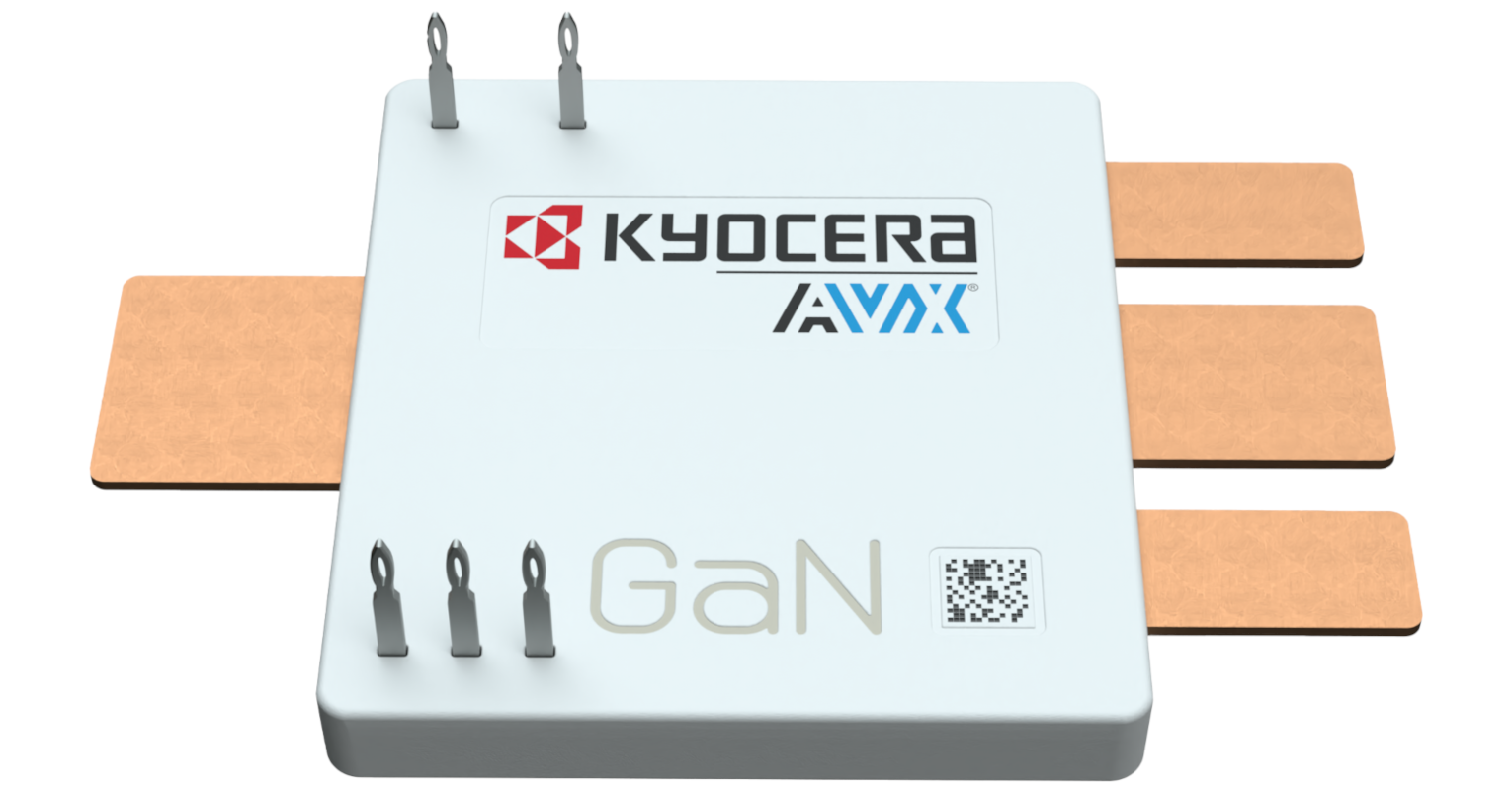

KYOCERA AVX Salzburg and VisIC Technologies expand their collaboration within e-mobility on next-generation GaN technology

Ness Ziona, Israel/ Salzburg, Austria 26/10/2022

Combining KYOCERA AVX’s leadership in discrete and module packaging along with VisIC’s expertise in GaN power devices to offer cutting-edge products, including the highest efficiency power module for lead EV OEM and Tier 1 traction inverters

KYOCERA AVX Salzburg, Kyocera-AVX Salzburg, a leading international manufacturer and supplier of advanced electronic components for the automotive industry with production sites in North America, China and Europe, and VisIC Technologies, a global leader in Gallium Nitride (GaN) solutions for high-voltage automotive applications, announce the expansion of their collaboration. The partners combine their strengths in packaging, assembly, and GaN wafer technologies with the target of providing high current components for high voltage applications such as charging and e-drivetrain.

The collaboration expansion aims to fulfill the demand of the automotive industry for reliable and highly efficient power solutions that will save EV costs. With the best thermal resistance, discrete GaN devices and half-bridge modules will be essential for future On-Board-Chargers (OBC) and traction Inverters, optimizing weight, size, costs, and driving range.

Based on VisIC’s 2nd generation, lowest RDS (on) D3GaN switches, the power module, which will provide groundbreaking power density and performance, has already been adopted for the next generation inverter sample of a major 1st tier automotive manufacturer.

In addition to the above collaboration developments, the companies have also achieved an approach to high-voltage battery disconnection, based on GaN power switches, through effective cooperation in a very short time. With the fastest switching time, the current and, therefore, thermal stress of the battery and board net can be limited. This design will be available for lead projects this year.

“The electrification of the automotive industry has generated significant demand for power components, which we foresee to continue its strong growth for the next decade. “, said Dr. Tamara Baksht, CEO and co-founder of VisIC Technologies. “Together with KYOCERA AVX Salzburg we will provide packaged discrete GaN devices and die-based power modules for major EV OEM and Tier 1 designs.”.

VisIC’s D3GaN technology was developed for the high-reliability standards of the automotive industry and for the lowest losses. It also simplifies the system solution and enables highly efficient and affordable powertrain platform solutions. These benefits are well perceived by premium automotive customers VisIC has been working for several years with.

“Gallium nitride semiconductors are the key to efficiency improvements and increasing the driving range of electrified vehicles. This technology offers significantly better switching speed and smaller and lighter package size, thereby reducing total system cost.”, said Martin Knosp, Product Line Director at KYOCERA AVX Salzburg. “We are happy to expand our cooperation with VisIC Technologies, leveraging our advanced design and manufacturing abilities to create more GaN products and devices for better serving the booming EV market demands.”.

VisIC Technologies is a world leader in GaN semiconductors for EV applications, focused on high-power automotive solutions. It’s efficient and scalable products are based on deep technological knowledge of gallium-nitride and decades of experience. VisIC is committed to providing a step function improvement in terms of size and cost of energy conversion systems and is dedicated to high-quality customer support at all development phases. VisIC offers high power transistor products based upon compound semiconductor Gallium Nitride (GaN) material aiming to provide products for cost-effective and high-performance automotive inverter systems.

KYOCERA AVX is a leading global manufacturer of advanced electronic components engineered to accelerate technological innovation and build a better future. As a wholly owned subsidiary of KYOCERA Corporation structured to capitalize on shared resources and technical expertise, KYOCERA AVX has an expansive global footprint comprised of several dozen research, development, and manufacturing facilities spanning more than 15 countries and staffed with talented personnel dedicated to innovation, component quality, customer service, and enabling a brighter future through technology. KYOCERA AVX designs, develops, manufactures, and supplies advanced capacitors, antennas, interconnects, circuit protection and timing devices, sensors, controls, filters, fuses, diodes, resistors, couplers, and inductors optimized for employment in the international 5G, IoT, aerospace, automotive, consumer electronics, industrial, medical, and military markets.

Partnership with Nexperia agreed

KYOCERA AVX Components (Salzburg) GmbH and Nexperia agree Partnership for Gallium Nitride Automotive Power Modules.

Over 30 years of delivering application-specific power electronics to the automotive industry KYOCERA AVX Components (Salzburg) GmbH is going to grow this business with a partnership covering gallium nitride (GaN) automotive power modules with NEXPERIA, the expert for essential semiconductors and components.

This partnership offers more freedom for individual designs with high performance and scalability. Focusing on designs with high power density, small footprint and outstanding reliability, enables a simple and full powertrain integration (OEM). By selecting state-of-the-art packaging materials and assembly technologies a design-to-cost target can be met upon customer requirements in future.

» Learn more about our power modules

Career at KYOCERA AVX Components (Dresden) – Let’s meet!

As a sponsoring partner or as an exhibitor, we are regularly present at events, because we want to get to know you!

The formats are digital or in person, trainee and student days, trade fairs or sporting events.

We are on site and look forward to interesting contacts!

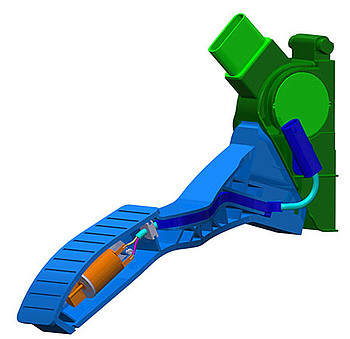

Proven pedals for future truck generations

Leading European manufacturer KYOCERA AVX Components has launched the latest series of accelerator pedals for trucks – and they’re all set for whatever demands the future may hold.

Leading European manufacturer KYOCERA AVX Components has launched the latest series of accelerator pedals for trucks – and they’re all set for whatever demands the future may hold.

Electronic accelerator pedals for passenger cars from several well-known car manufacturers were already well established in the market when the first development of an electronic truck pedal went into series production in 2004. Since then, KYOCERA AVX Components has steadily and successfully expanded its portfolio in the truck sector, and today, it is one of the world’s leading manufacturers of truck pedals.

Proven mechanics with state-of-the-art electronics – many of the leading truck manufacturers rely on this, with their vehicles having to withstand the highest loads. In Asia too, especially in India and China, the pedals have conquered a market and in many cases prevailed over the local competition. Optimum fuel efficiency via the driveline is important, as is the ‘feel’ for the driver. After all, the accelerator pedal is the interface between the driver and the machine, often over many thousands of hours and more than a million kilometers.

Accelerator pedals from KYOCERA AVX Components have proven themselves millions of times in the field, and are already used in e-trucks. They combine the advantages of state-of-the-art technology with proven components at low weight, and are proven to be very robust and durable. The latest generation of pedals is able to provide feedback to the driver about their driving behavior, or communicate information from supporting systems via a haptic signal. A suspended pedal variant also offers add-on options for retrofitting the haptic module at a later date. Read more about this pioneering technology here.

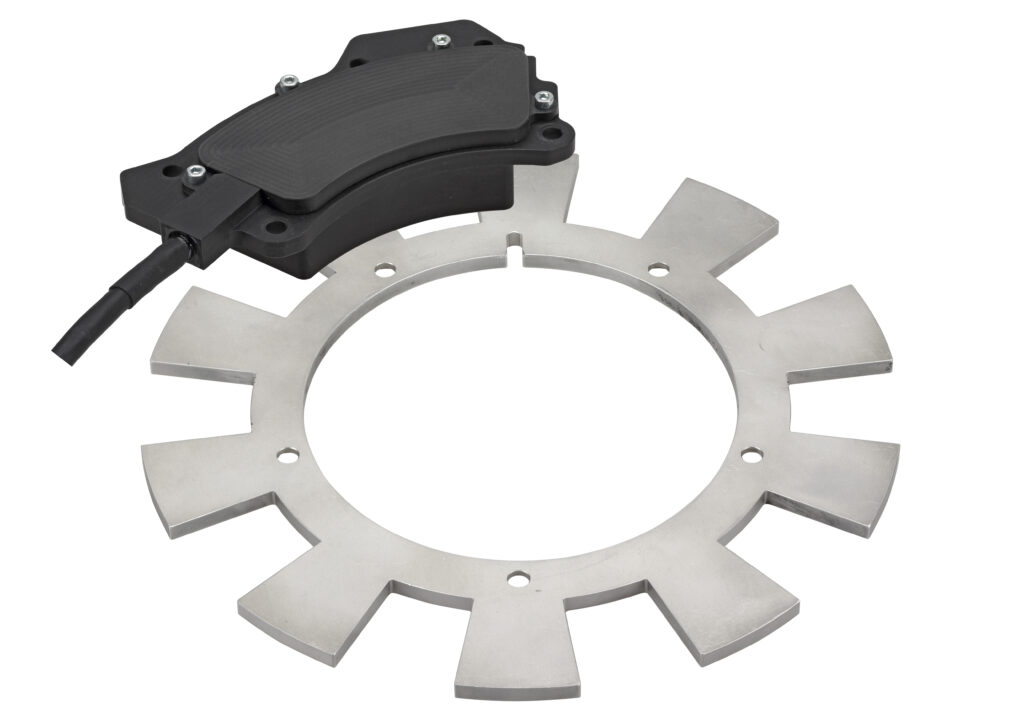

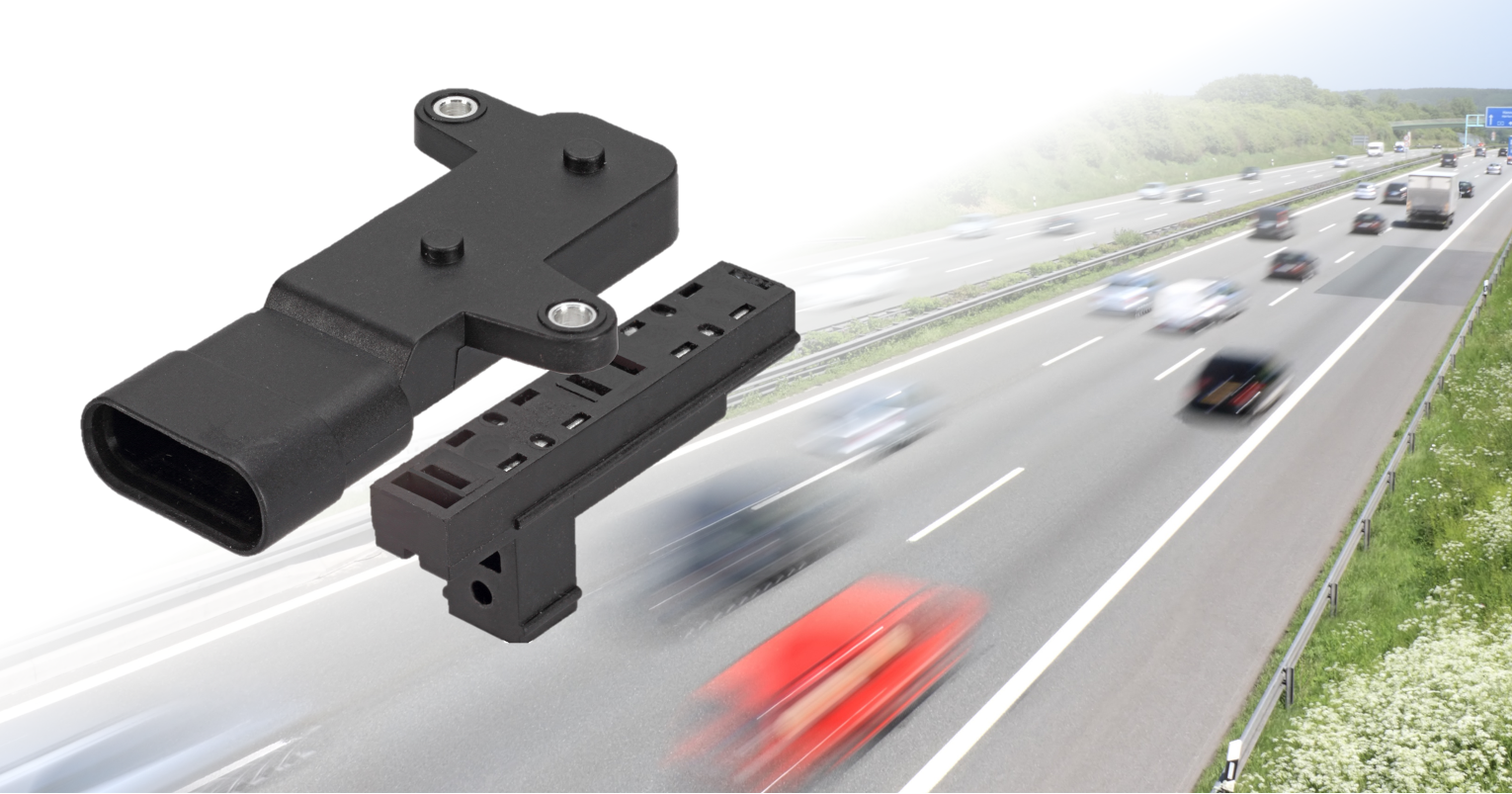

Position sensors supportASIL D capable assistance systems

Position sensors by KYOCERA AVX support ASIL D capable assistance systems for braking force control and recuperation

KYOCERA AVX stands for the development and worldwide production of position sensors based on versatile technologies, and with different electronic interfaces. Our position sensors have already proven themselves millions of times in automotive applications, and take on important functions in new types of assistance systems.

Position sensors for the assistance of braking processes

By sensing the pedal position, the driver’s braking demand is detected and interpreted by the downstream systems. Common applications are brake boosting and emergency braking assistance, i.e. safety-related systems. In the future, they will be used across all vehicle classes to increase safety on the road. Position sensors from KYOCERA AVX require little installation space and can be integrated economically using modular concepts.

Position sensors initiate recuperation

In electric vehicles it is also about the recuperation of the braking force, which replenishes the battery charge and thus increases the available range. Depending on the vehicle model, the rate of recuperation is specified by the electronics, and the process is initiated by detecting the accelerator pedal or brake pedal positions. With the appropriate system settings, it is even possible to drive a vehicle in normal road traffic using only the accelerator pedal, the brake being needed only for emergency braking.

Safety-relevant functions for position sensors

The requirements for these systems are very high, and again the detection of position is the trigger for safety-relevant processes in the vehicle. KYOCERA AVX supports the application with position sensors that meet corresponding FUSI requirements on the ASIL C level.

Broad technology base and many years of field experience

Different sensor technologies allow individual tailoring of the product characteristics to the respective application. Interfaces including analog, PWM, PSI5, SENT, CAN, LIN and other protocols are possible.

The individual design of position sensors is based on the selection of the optimal technology for the application, in combination with a suitable mechanical interface. Based on an advanced overmolding technology developed by KYOCERA AVX, we use the excellent properties of thermoplastic and thermoset to create solutions with integrated sensor technology. However, we are also happy to offer molded or laser-welded cover solutions if this is the optimal solution for your application.

We are at your disposal for inquiries and technical discussions: feel free to contact us, or find out more by watching a short video on position sensors, available as part of our virtual exhibition stand.

SPINpad Technology

A High Speed Rotation Position Sensing Technology for next generation mobility

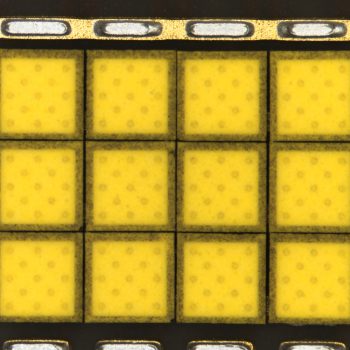

LED-Matrix

Highly efficient matrix beam solutions for electromobility

Eco-Matrixbeam modules for matrix headlamps from KYOCERA AVX Components (Salzburg) support various light functions with very low energy consumption and maximum freedom of design

Independent from the type of engine the overall energy consumption of all main and auxiliary electronic units has an impact on the actual range between refueling or charging.

Eco-Matrixbeam reduces the energy consumption and power loss for an increased range

While for cars with conventional engines, for hybrid electric vehicles (HEV) and fuel cell electric vehicles (FCEV) the above-mentioned facts cause a higher fuel consumption, but affects directly the range for battery electric vehicles (BEV). Therefor the overall power loss of state-of-the-art headlamps and rear lights plays an even bigger role. Especially LED matrix head lamps with different light functions and an increasing pixel count provide several advantages for safe driving at dark and wet conditions. But on the other hand, these accomplishments are attended by an increasing energy consumption of different electronic modules. So, with the Eco-Matrixbeam KYOCERA AVX Components (Salzburg) has developed an alternative solution for matrix applications featuring low energy consumption compared to conventional concepts, but with unrestricted functionality. Primarily this will be accomplished by means of highly efficient optics in combination with customized LED matrix light sources. Beside the efficiency new standards are set concerning optics size and the weight of the entire electronic module.

Eco-Matrixbeam sets standards concerning scalability despite very small module size

The Eco-Matrixbeam technology enables very slim headlamp designs of modern vehicles and represents a future-proof scalable solution with its small optics. Although the compact module size facilitates an implementation into headlamp housings with limited space. Depending on the requirements for light distribution and functionality of the matrix beam individual types of the LED light source as well as the optics can be realized by considering specific technology guide lines. Furthermore, small module sizes provide low system costs also for individual applications.

Eco-Matrixbeam from AB Mikroelektronik: outstanding optical efficiency without restrictions for functioning and driving safety

The LED module features an outstanding optical efficiency along with slim optics and small module size. Additionally the optimized thermal performance of the Eco-Matrixbeam technology enables an application in vehicles with slim, modern headlamp designs, providing lower fuel, respectively energy consumption without tradeoffs concerning functioning and driving safety.

» For more information, please visit the LED modules product category

» Learn more about our portfolio for E-Mobility applications